There's no such thing as impossible! We'll find the right cooling solution for you.

Feasibility analyses of cooling concepts protect your investments

Do you have an innovative, perhaps even brilliant product idea for an electronic device? Congratulations! And our advice based on 30 years of product development: Make the topic of component cooling a top priority in your project planning! After all, if it only becomes apparent in the prototype phase or even in series production that your device is getting (too) hot, your cost and time plans will quickly become a waste of time.

Do you have an innovative, perhaps even brilliant product idea for an electronic device? Congratulations! And our advice based on 30 years of product development: Make the topic of component cooling a top priority in your project planning! After all, if it only becomes apparent in the prototype phase or even in series production that your device is getting (too) hot, your cost and time plans will quickly become a waste of time.

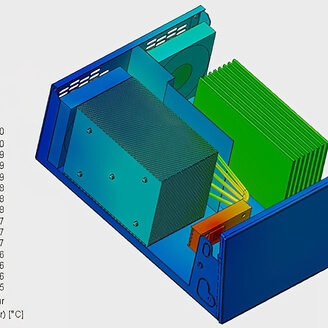

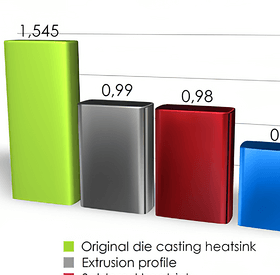

Simulation of heat sink alternatives

Professional and honest advice from our cooling experts will make a significant contribution to keeping your development costs within a predictable range. This is not only due to the experience that our long-standing employees have gained in hundreds of projects. They also use realistic thermal simulations to run through a wide range of heat sinks, system set-ups and housing arrangements in advance. In these simulations, we can compare the relevant factors for your performance- and cost-optimised heat sink solution with several alternatives. Without complex prototypes and test procedures. The most important factors include

- Cooling capacity

- size

- weight

- Unit costs

You receive a valid basis for decision-making in order to save valuable time and unnecessary costs in the subsequent development steps - manufacturing processes, prototype construction, load tests, series production.

Let's talk about your cooling task!

Dr Andreas Engelhardt

Head of Development and Design

a.engelhardt@ekl-ag.de

Make an appointment Enquiries by e-mail

Dr Andreas Engelhardt

Head of Development and Design

a.engelhardt@ekl-ag.de

Make an appointment Enquiries by e-mail

We take care of your electronic 'hotheads'

Especially in the area of cooling, cost reduction plays an important role in successfully placing an electronic product on the market and keeping it reliable. After all, it is not the heat development in the device that you are selling, but the excellent function and flawless interaction of all components. Power loss as waste heat is an "annoying" side effect that must be dissipated more and more effectively with increasing performance and miniaturisation in electronics. Without making the product more expensive with complex cooling solutions just for cooling the components.

Avoid cost explosion and development loops through feasibility studies

The most expensive experience you can have as a manufacturer of an electronic device is the overheating of a product that has already been mass-produced. Apart from the dissatisfaction of your customers and possible damage to your image, you will be faced with new time-consuming and labour-intensive development loops.

Just a worst-case scenario? Unfortunately not! You would be surprised how often we have been called out for "outpatient heat treatments". In EKL you will not only find a supplier of component cooling, but also a committed development partner who always thinks along with you. We see it as our responsibility to provide our customers with a reliably functioning cooling solution at a fair price and to deliver the series heat sink in the shortest possible time.

Just a worst-case scenario? Unfortunately not! You would be surprised how often we have been called out for "outpatient heat treatments". In EKL you will not only find a supplier of component cooling, but also a committed development partner who always thinks along with you. We see it as our responsibility to provide our customers with a reliably functioning cooling solution at a fair price and to deliver the series heat sink in the shortest possible time.

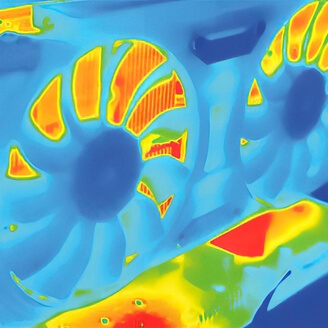

From technical concept to thermal simulation to near-series prototype

The experience of EKL's development engineers provides the initial ideas for the ideal cooling system for your components. With the help of computer-aided thermal simulation, we run through these different concepts and virtually test their feasibility and cooling performance. However, only the real, near-series prototype with real measured values provides the certainty that the selected cooling solution will actually fulfil all the requirements of your series product.

Your advantages when working with EKL

- Personal contact throughout the entire project

- Short response times

- High sense of responsibility, flexibility, innovative strength

- Quick start of your project

- Rapid delivery of functioning prototypes and finished series products

- Realisation of specific test plans for production, final inspection, incoming and outgoing goods inspection

- Long-standing manufacturing partnerships with quality leaders

Get to know further EKL expertise

EKL - Everything from a single source

The temperature of electronic components must remain within the tolerated range, as excessive heating can shorten their service life and impair their performance. EKL provides you with expert support in solving these heat problems efficiently and economically using passive heat sinks, fans, heat pipes, liquid heat sinks or other thermal management technologies.

EKL is therefore your perfect solution partner for cost-optimised temperature regulation of all components in your electronic device. We are at your side in every project phase, from the initial idea, design and prototype construction through to series production - and beyond!

The temperature of electronic components must remain within the tolerated range, as excessive heating can shorten their service life and impair their performance. EKL provides you with expert support in solving these heat problems efficiently and economically using passive heat sinks, fans, heat pipes, liquid heat sinks or other thermal management technologies.

EKL is therefore your perfect solution partner for cost-optimised temperature regulation of all components in your electronic device. We are at your side in every project phase, from the initial idea, design and prototype construction through to series production - and beyond!

Personal point of contact

From the initial project phase to the delivery of your customised cooling technology, you will always have a personal point of contact at EKL We are always available to provide you with competent and responsive support.

Full service from the idea to logistics

Concentrate your core competence on product development. We offer all project services relating to cooling - from the initial consultation, idea development and thermal simulation, prototype construction and optimisation, through to punctual delivery and reliable logistics and warehousing.

Variety of manufacturing technologies

We are one of the heat sink manufacturers with the widest range of manufacturing technologies. This enables us to offer a service portfolio that is designed for the development and production of your truly best cooling solution - at an excellent price-performance ratio.

Performance optimisation + cost optimisation

EKL actively supports you in reducing your manufacturing costs without compromising quality or performance. Product cost reduction is an important aspect that we achieve for you through efficient design, careful material selection and reliable manufacturing partners.

Pre-assembled assemblies + packaging

We actively assist your production staff by supplying pre-assembled assemblies. This not only reduces your labour costs per device, but also guarantees the highest quality. Your sensitive heat sinks or assemblies are protected for transport using customised packaging.

Warehouse and logistics in Germany

With over 1100 pallet spaces, we offer tailor-made logistics solutions and minimise your storage costs through stockpiling and consignment stock, just-in-time deliveries, coordinated delivery schedules and flexible shipping options for individual requirements.

Let's talk about your cooling task!

Frank Sichler

Sales Manager

+49 (0)7561 9837-47

f.sichler@ekl-ag.de

Make an appointment Enquiries by e-mail

Frank Sichler

Sales Manager

+49 (0)7561 9837-47

f.sichler@ekl-ag.de

Make an appointment Enquiries by e-mail